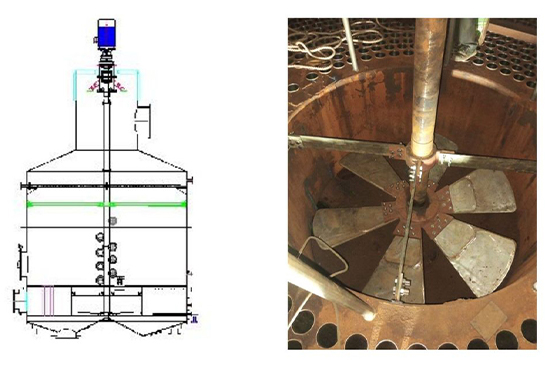

Mechanical Pan Circulators

Mechanical Pan Circulators are used in the Sugar industry to enhance the efficiency of the crystallization process. They can be used for A, B and C massecuites. Mechanical Circulator for vacuum pans reduces boiling time, sugar color and increases pan yield. It boosts the heat transfer efficiency by inducing a higher rate of heat transfer and evaporation. With an increase in heat transfer coefficient, the strike time reduces up to 30%, which in turn increases the production capacity of the unit.

Material of Construction: Carbon Steel I Stainless Steel

Applications: Sugar

Advantages :

- The boiling time reduces by 25-35%.

- Strike level or the working volume can be increased.

- Even and uniform grain size can be maintained.

- Low pressure vapour can be used for boiling. 6. Saving in steam consumption due to reduction in boiling time.

- Circulation rates are fairly maintained and thus conglomerate formation is minimized in high grade massecuites and so is the color development. Whereas in the low grade massecuites, the exhaustion of mother liquor improves.